Surface coating

A high-quality coating can significantly increase the service life of components. For good adhesion, uniform application and resistance of the layer to various environmental influences, the components are mechanically and / or chemically pretreated before coating.

The selection of the manufacturing process for coating depends on the base material. OT Schwerin offers the following coating processes:

Diffusion coatings (CVD)

- Chromation in the packing process

- Alitation in the packing process

- Alitation with slurry

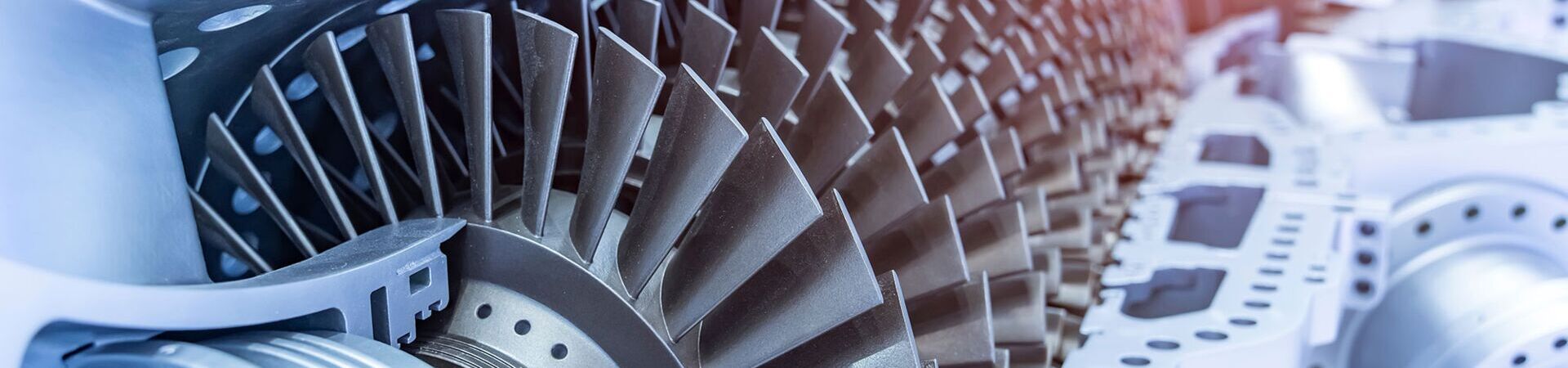

Compressor coating

- Coating of individual blades, compressor impellers and guide disks with special aluminum-pigmented ceramics via manual atmospheric spraying

- Hot coating of compressor shafts (new construction / service)

- Anti-fouling coating with Teflon (PTFE)

Thermal spray

- MCrAlY (metallic corrosion / oxidation protection layer) via high-speed flame jet spraying (HVOF)

- TBC coating with ceramic thermal insulation layers via APS

- Running-in layer (abradable coating)

- Antifretting (copper, nickel, indium coating) in connection with molybdenum disulfide application via APS