Welcome to OT Oberflächentechnik GmbH & Co. KG

OT Oberflächentechnik GmbH & Co. KG (OT Schwerin) is an innovative, certified and future-oriented company with modern equipment and qualified employees.

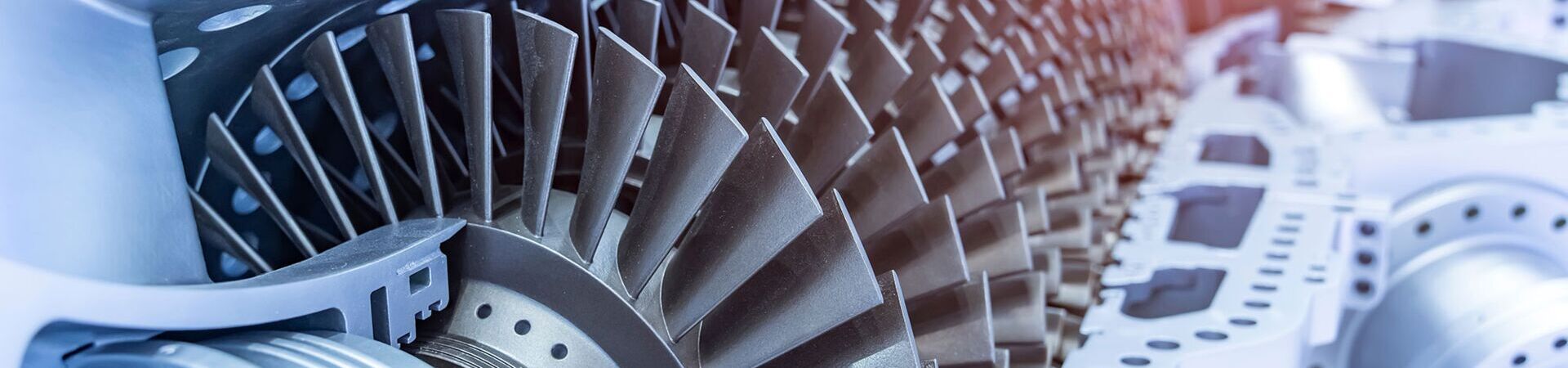

It specialises in the complete refurbishment of components in stationary gas and steam turbines, aircraft engines and compressor units, and in surface coating with metallic and ceramic materials. The company offers its customers individual applications for the processing of components made from various, mainly high-temperature materials.

Over 25 years of know-how and experience guarantees that OT Schwerin always provides its global customer base with high-quality fulfilment of all orders, delivered on schedule.

Surface technology services

Refurbishment

Decoating, component cleaning, heat treatment, non destructive testing, welding, metallopraphy...

more Information, Contact

Surface coating

Diffusion coating (CVD),

thermal spraying (HVOF), atmospheric spraying...

more Information, Contact

Mobile coating service

Worldwide coating of components from stationary gas turbines directly on site in power plants or work shops...

more Information, Contact

Aviation

Welding (Nadcap), salt bath cleaning, coating, heat treatment, non destructive testing...

more Information, Contact

Certifications

Quality management, health and safety management, environmental management, Nadcap...

more Information, Contact

Jobs

Working at OT Schwerin,

current vacancies,

unsolicited applications...

more Information, Contact

Do you have any questions about our services?

Technical inquiries about coatings and refurbishment:

Current news from surface technology

Chromium(VI) measurements successfully passed again

In July, the annual measurements of chromium(VI) concentrations in the air during operations in the coating booths took place again. We are obliged to do this in order to maintain our exemption for the use of coating materials containing chromium(VI).

The concentrations in the air are measured in the preparation room, in the area around the coating booths and directly in the coating booths. In addition, we have measurements taken inside the full face masks of the coaters to ensure that the personal protective equipment is working appropriately and that our employees are not exposed to any health hazards. Furthermore, the chromium(V) concentration in the emissions from the exhaust of the coating booths is carried out.

Despite the high workload of the coating department, all measured values were again inconspicuous and the limit values were complied with.